Technical exchange

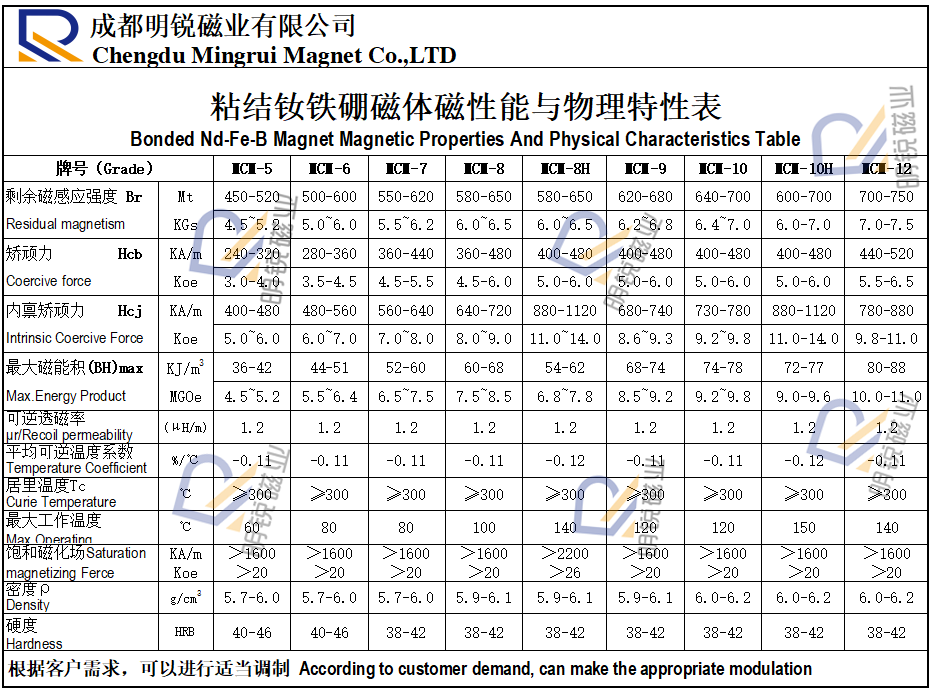

一、Performance parameters of bonded NdFeB magnets:

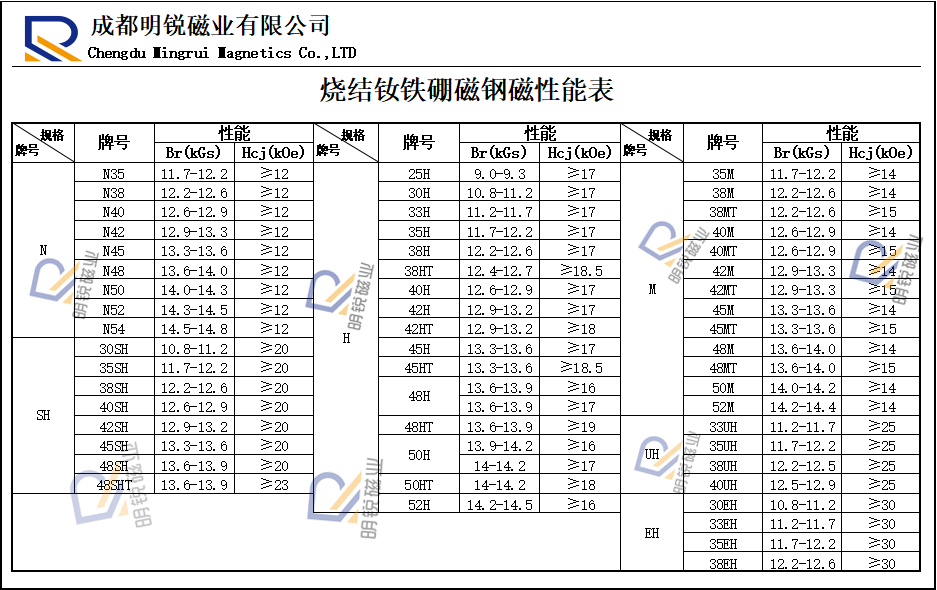

二、Performance table of sintered NdFeB magnets

三、Introduction of several common permanent magnet steels:

1、Bonded neodymium iron boron magnet: the shape and size of the product are guaranteed by the mold, with high dimensional accuracy and large freedom of shape, which can be made into ring, tile, block shape and other shapes without sintering and post machining; the number of magnetizing poles can be variable and in various ways, and the poles can be filled into multi pole, oblique pole, and the wave shape can be square wave and sine wave. Bonded NdFeB magnets are widely used in automobile motors, hard disk drives, stepping motors, water pumps, oil pumps, DC motors, brushless motors, starting motors and sensors.

2、Hot pressed neodymium iron boron magnet: the product is of nanocrystalline structure with high density; it has high magnetic properties, and the maximum radial magnetic energy product of the magnetic ring is 240-390kj / m3; the magnetic ring is oriented along the radial direction, and the radial magnetic properties are even, which can make the motor run quietly, and the torque output is smooth; the number of magnetic poles and the rotation angle of the magnetic poles of the magnetic ring do not need to be predetermined in the forming process, only by designing and changing the magnetic coil, customer The magnetization waveform of the magnetic ring can be magnetized as square wave and other special magnetization waveforms according to the user's requirements. Hot pressed magnet has been used in automobile motor, electric tool, servo motor, small precision brushless motor and other fields of energy-saving motors. The company is the second one in the world and the first one in China with the capability of mass production of hot pressed NdFeB magnets.

3、SmCo magnet: it has a high operating temperature (the maximum operating temperature is 550 ℃), and its temperature stability and chemical stability are far more than other permanent magnet materials. It can work in a long-term harsh environment such as high temperature, high humidity, strong demagnetization and nuclear radiation without surface treatment. SmCo magnets (including SmCo5 and Sm2Co17) are widely used in aviation, aerospace, military electronics, automobile, sensor, petrochemical industry, magnetic drive and other fields.

4、Injection magnet (plastic magnet for short): the injection magnet is molded by injection molding process, so the product can be designed into a more complex shape, as well as a magnet assembly with shaft and gear inserts; compared with the commonly used sintered magnets (such as sintered rare earth permanent magnet and sintered ferrite), the injection magnet has better toughness and is not easy to crack under the impact load. Injection magnet can be widely used in household appliances, automobiles, office equipment, 3C products and other fields.

5、Sintered Nd-Fe-B magnetic steel: sintered NdFeB permanent magnetic materials are made of powder metallurgy process. The melted alloy is made into powder and pressed into pressed blank in magnetic field. The pressed blank is sintered in inert gas or vacuum to achieve densification. In order to improve the coercivity of magnet, aging heat treatment is usually required. Sintered NdFeB permanent magnetic materials have excellent magnetic properties, which are widely used in the fields of electronics, electric power machinery, medical equipment, toys, packaging, hardware machinery, aerospace and other fields. The more common ones are permanent magnet motor, loudspeaker, magnetic separator, computer disk driver, magnetic resonance imaging equipment and meters.

Follow US